Description

When it comes to controlling erosion it is essential that a dimensionally stable, durable and permeable erosion control fabric is installed. For this application, our fabric is specifically designed for challenging and rugged environments where the primary goal is to control erosion in a specific area of the landscape. This non-woven geotextile is made of 100% polypropylene and contains no fillers or substitution composites. Our erosion control fabric provides an approximate weight of 8 oz / sq. yd.* and a grab tensile strength of 205 lbs. which provides an elevated level of tear resistance. This fabric ships from four regional warehouses and is available in a variety of different roll sizes.

*Approximate Weight, Why?

In the world of geotextile fabrics, often times technological advances in fabric production allows for, on occasion, a slightly lighter weight to meet or exceed the standard performance of a weighted fabric. In these cases the actual material weight is not specified on the spec sheet. Regardless of the actual weight of the fabric, when comparing fabrics what really matters is the actual performance of the fabric under testing.

Fabric at a Glance

Permeable

Strong

UV Resistant

Rot Resistant

Mildew Resistant

Rodent Resistant

Insect Resistant

Heavy-Duty

Erosion Control Fabric

Estimated Material Lifespan:

25 years

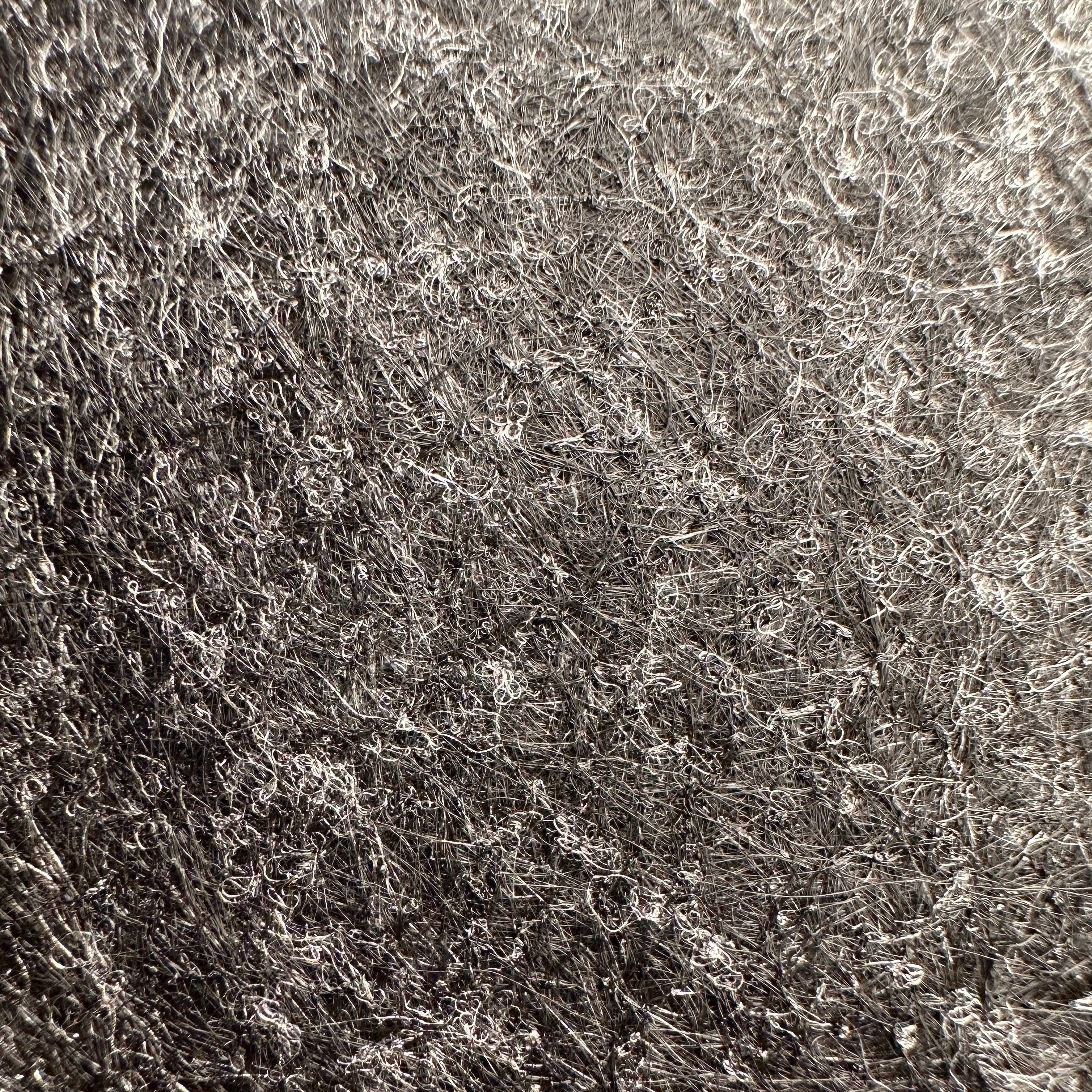

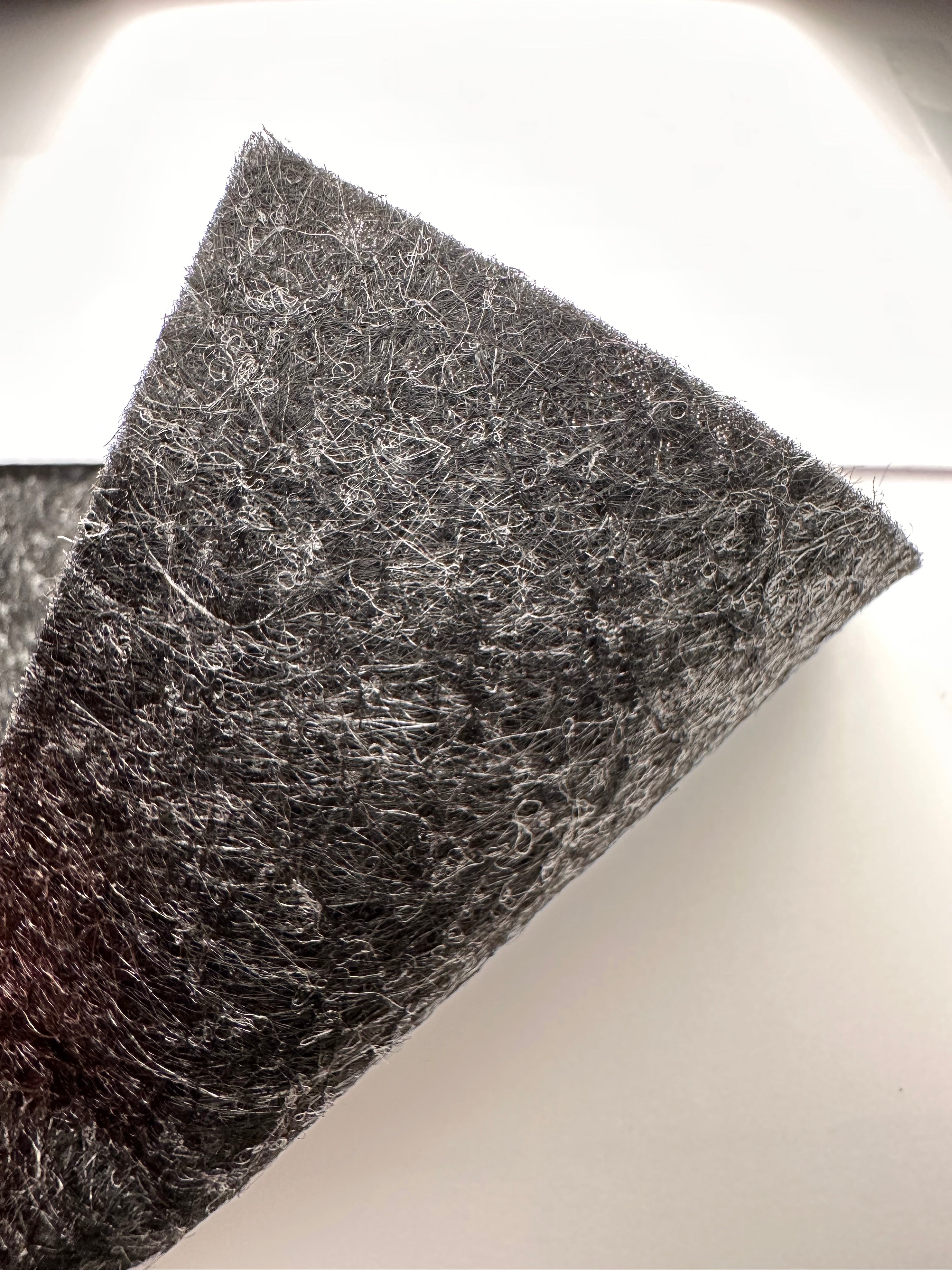

Fabric Texture:

Felt, fuzzy on both sides

Fabric Weight: 8.0 / sq. yd

Download Product Specification SheetRequest Formal QuoteCG

Commercial Grade

Each of our fabrics is commercial-grade and designed for years of continuous in-ground use. This fabric is ideal for permanent installations where long term durability is required.

Volume Pricing

Fabric Pros can provide volume pricing for larger orders totaling more than $5,000. Please fill out the quote request form at the link below and we will provide you with a written quote within two business days.

Request Volume QuoteQuestions?

Do you have product related or purchasing questions? We are happy to help, just give us a call:

(800) 214-5028

Commercial Grade Erosion Control Fabric

For customers looking for the best drainage fabric available, we have recommended this fabric to thousands of customers on both residential and commercial installations. This fabric is for the customer who wants the best, not the cheapest.

Tip: Look for Detailed Specs

Large online shopping websites are flooded with fabrics claiming to be the "highest quality". Always look for detailed specs with testing results. If you don't see a spec sheet download don't believe the claim.

Installation

Installation of our drainage fabrics can vary slightly based on jobsite specifics and the exact application. The following are general steps are for a standard straight-forward installation.

Step 1:

Remove all debris, rocks and unwanted plantings from the installation area.

Step 2:

Place the fabric roll in the installation area and unroll. Once the fabric is unrolled, cut the fabric to fit. At seams, it is best to overlap the fabric by 18-24".

Step 3:

Use ground staples to secure the fabric to the installation area staggering at 1.2 staples per square yard. Cover the area with rock or ground cover to protect the fabric from sunlight and enhance the overall look of the installation.

Why Spend More with Fabric Pros?

You’ve probably seen “high-quality erosion control fabric” on various big box retailers websites. Usually priced really cheap. Why spend more with us? Think of the project as a whole. What is the most expensive aspect of your project? Typically it’s the labor, followed by hardscape material, plantings and ground cover. On many projects the fabric cost is less than 1% of the total cost of the project. What is one of the first materials that is installed? Typically any sub grade than the fabric. If you put down the wrong fabric and there is an issue, in many situations the entire project has to be redone costing the owner thousands of dollars and a re-installation of everything above the fabric. Case in Point: buy fabric that has been time tested, widely used by professionals and is ASTM tested. You’ll pay more but at least you’ll know what you are getting. Fabric that is directly imported from overseas and posted to a “large online retailer” with countless “5 star reviews” should be approached with a great deal of caution.

Clear Direction on the Right Fabric to Use

From thousands of customers over 20 years we know what the most appropriate fabric is for the given application and we make it simple. We don’t throw 50 options at you to decipher. We present the most commonly used fabric by the professionals for the application.

Tested, Commercial-Grade Fabrics

Testing data helps you as the customer know what you are buying. More often than not, stores selling economy-grade fabric do not provide specification information with ASTM testing data. This is intentional.

We Ship Fast

When you place your order with us we make every effort to process your order right away. If your order is placed in the morning there is a strong chance that we can get it picked up same day by the shipping company.

We Pick Up Our Phone

Have you ever ordered a product online and for some reason needed to call the company? After spending 20 minutes searching for the phone number you finally call and get an annoying menu and eventually a person who doesn't seem to really care?

Not with Fabric Pros. We hate menus so we don't have one. When you call you get a person who is willing and actually able to help every time.

What Else Makes our Erosion Control Fabric Different?

Our Erosion Control Fabric is

100% Polypropylene

Our erosion control fabric is composed of 100% polypropylene. No fillers and no economy-grade substitutions. Polypropylene is the ideal material for an erosion control layer as it is both strong and very permeable. When economy materials are used in conjunction with polypropylene, strength and permeability ultimately suffers, leading to possible fabric failure and ultimately drainage issues. For permanent, long-term erosion control installations look for fabrics that are explicitly labeled as “100% polypropylene”.

Our Erosion Control Fabric is Needle Punched

in a Random Pattern

High quality erosion control geotextile fabrics rely on the process of needle punching fibers in a random pattern to produce the high strength and highly permeable material which is ideal for this particular application. The random nature of the tiny polypropylene strands provide heightened strength and more efficient permeability when compared to non-randomized non-woven fabrics.

How Long Will Shipping Take?

Our fabrics ship from four different distribution warehouses located in the west coast, south, midwest and north east areas of the United States. Most of our fabrics are stocked at all four locations and will ship from the location nearest to you to minimize transit time.

Our "Approximate" Transit Map

If everyone has learned one thing in the last few years it's that delivery dates aren't exact.

Most orders require 1 business day to ship. The shipping map to the right is "approximate" and does not take into account order processing time. (typically one business day or less) Sometimes a fabric will be out of stock at the specific warehouse closest to you and will have to ship from a further warehouse. This can impact the transit time. It is always a good idea to order your fabric a full week before you actually plan in installing. It will most likely show up days sooner but it's always better to be safe than sorry.

A Fabric for Nearly Every Application

Looking to do something different? View our selection of fabrics below for nearly every application.

Is Your Project a Bit "Outside of the Box?"

Don't worry, we probably have a fabric that will work great for whatever you are trying to do too! Feel free to give us a call at (800) 214-5028. We're happy to provide some guidance on the fabrics that you may want to consider for your project.

The Difference Between Woven & Non-Woven Geotextile Fabric

As defined in the Cambridge Dictionary: A strong material used to protect or hold soil in place, small stones, and water. Can be used in building or creating something like a garden.

Brief History

In the beginning, geotextiles were meant to be used as a substitute for granular soil filters. This began in the 1950s when R.J. Barrett used geotextiles behind precast concrete seawalls, under precast concrete erosion control, beneath large stone ripraps, and other erosion control operations.

Landscaping fabric has been playing a big role in many landscaping projects for some time now. This fabric filter separates and reinforces for excellent filtration and drainage purposes. There is no doubt that not all kinds of fabric are good choices for your landscaping projects. There are many differences between fabrics and their properties to take into consideration before deciding what fabric is right for your project.

Woven and non-woven geotextiles offer their own individual strengths and weaknesses when it comes to installation. Some fabrics will go beyond your expectations while others will not work out as well as expected. In most cases, this is based on the properties and what they have to offer for different applications. In this article, we are going to help you out by showing you their similarities and where they should be used in a standard installation.

Erosion Control Installation

Types Of Landscaping Geotextiles

Geotextiles offer excellent separation, filtration, and drainage. This is very important when subgrade materials are saturated for a good portion of the year or you are facing many freeze-thaw cycles during the winter months. The upward movement of the subgrade soil into the base material is caused by the pressure that the pavement experiences. As an example, when you step in mud, your boot becomes the catalyst pushing down on the mud causing a shift upwards and horizontally.

Using geotextile the stabilization of the base material helps to spread the load out over a larger area because the geotextile offers tensile strength to the base material. Geotextiles offer better filtration allowing water to spread out over a larger area due to better control over the drainage water. Geotextile's properties for drainage will allow water to freely flow through the fabric.

When choosing the right geotextile for your project, there are some factors you need to take into consideration. Before getting into those factors, you have to learn more about the two main types of geotextiles and understand what their properties are.

Woven Geotextile Landscape Fabric

Woven geotextile is made of polypropylene filaments that are connected to a network offering more stabilization strength than non-woven geotexiles.

Woven geotextile fabric is used for heavier dynamic and static load projects including driveways for additional reinforcement by spreading the load over a wider range. In areas where the subsoil is soft and unstable or water will not penetrate through the subgrade, choosing woven geotextile for drainage into the subgrade will probably be your choice. Drainage is always important. On the other hand, if you are not getting the drainage you need, you can install a drainage system using perforated or solid pipes and drains to collect the water and then allow it to exit the system. Either way, you should not allow water to create a reservoir and stand for long periods of time as it can lead to many unwanted issues over time.

About Non-Woven Geotextile Landscape Fabric

Non-woven geotextile fabric is made of polypropylene fibers that are randomly connected through a network. These small fibers feel a lot like felt. This non-woven geotextile fabric offers separation, filtration, and drainage once installed. Non-woven geotextile fabric comes in a variety to choose from. Its strength varies, the heavier varieties are perfect for hardscape installation under interlock and retaining walls as well as for other landscape drainage projects. This fabric is considered a commercial-grade landscape fabric versus a weed barrier fabric.

The biggest difference between woven and non-woven geotextile is the drainage and reinforcement. Because non-woven geotextile fabric allows water penetration and drainage functions that, in comparison, goes well beyond woven geotextile. The non-woven geotextile is the primary choice for areas that require excellent drainage. For projects that experience pedestrian traffic, low dynamic loads, low static loads, hard subgrades, and the ability to drain freely, non-woven geotextile is the best choice.

Non-woven geotextile is very important in projects that require separation of material from cross-contamination while still allowing water to drain such as a French drain. In this procedure, a perforated drainage pipe is surrounded by a clean stone and wrapped all the way around with non-woven geotextile filter fabric.

There are other hardscape projects that require non-woven geotextile fabric such as a concrete overlay. The base of the concrete overlay is a hard material that does not require stabilization or reinforcement. What must be done, all water that enters the system must drain through and filter out then leave the system. That's why non-woven geotextile is so important for projects like this. Also, a non-woven geotextile is used as a retaining wall fabric. That said, a woven geotextile can be used for the foundation or base of the retaining wall. The rest of the wall is covered with non-woven geotextile for the lateral and top sections for separation, filtration, and filtration but not for reinforcement. This will allow water to penetrate through the backfilled section of the wall and then into the drain without removing the subgrade and soil material into the backfill material.

How To Install Landscape Fabric

When installing geotextile fabric, it should overlap at a minimum of 12 inches and increase as the subgrade becomes even softer as you progress. Also, the pieces should be shingled away from the foundation. In other words, the pieces from the foundation should be placed under the next piece. This will allow water to move from one piece to another away from the foundation without traveling underneath a piece of fabric.

As the geotextile is rolled out and cut, the pieces must be in tension as the base material is being prepared on top of it. All the wrinkles must be removed before dumping gravel on top and preparing the base. It's best practice to limit the amount of cut fabric as you possibly can. It's important when installing the fabric it will wrap up the sides of the project to offer better separation of the subgrade from the sides into the base material.

Erosion Issues in Field

Note - separation of the subgrade from the base material is an advantage for using a geotextile.

Referring back to the example of the boot, material under pressure from a load (or boot) has a habit of moving horizontally as well as upwards. The separation of the subgrade under tension of the geotextile will stop the upward movement of the subgrade into the base material by spreading the load out over a bigger area. Also, it will stop the horizontal movement of the subgrade from the sides of the excavation into the base material.

Grass Growing on Hillside

There are many advantages to installing geotextiles in your landscape project. There are factors that must be taken into consideration when selecting the right geotextile for your project. This article will help you make the best choice for the longevity of your landscape or hardscape project.

In Conclusion

Both woven and non-woven geotextile fabrics have played important roles in many different projects. Reading up and learning everything you can about the two fabrics and how they can work together or work better separately depending on the job. Geotextiles have come a long way and have improved many projects for better results and greater longevity.